Products

文章隐藏

FATEK Customized Solutions: Turning Client Challenges into Innovation Momentum

From factory floors to high-speed trains and hospital emergency rooms, seemingly minor issues can halt entire production lines or even jeopardize lives. While these challenges may lack glamour, FATEK holds firm that such real-world pain points are the very catalysts igniting technological innovation.

The "Angle Blind Spot" in Stamping Presses

Workers struggled to see pressing angles on stamping dies, relying on error-prone guesswork that risked die damage and workplace accidents. FATEK engineers pinpointed the core problem as visual accessibility, not mechanical precision.

Solution: Developed a rotary indicator system with automotive-inspired dynamic light rings for intuitive angle visualization, eliminating guesswork while enhancing operational safety.

The "Vanishing Signal" on Bullet Trains

Controllers malfunctioned due to cabin electromagnetic interference. Clients said: "Works in labs, fails on trains."

Breakthrough: Onboard testing revealed extreme interference. Redesigned circuit boards with shielded chips and anti-interference sealed connectors. Controllers now run stably at high speeds.

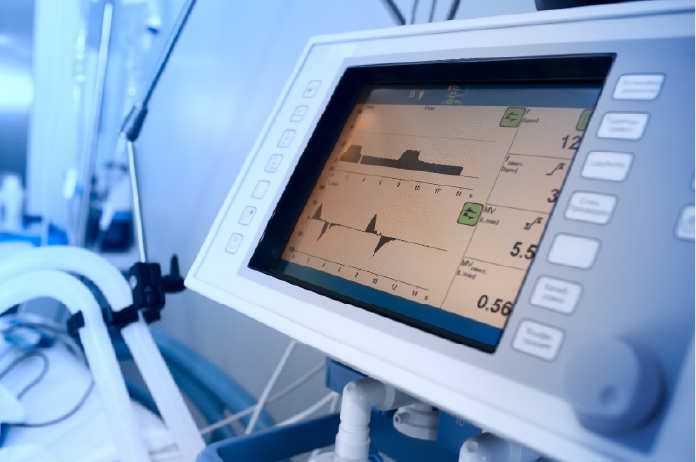

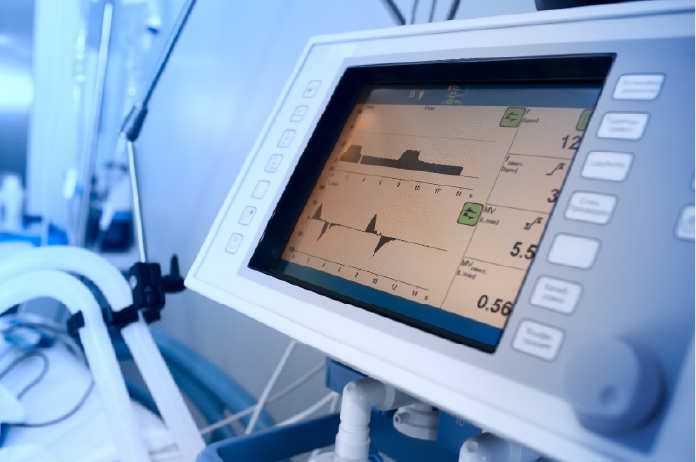

The "Lifesaving Button" During COVID-19

When ventilators faced part shortages, FATEK transformed industrial HMIs into medical monitors.

Emergency Fix: Rewrote code and optimized algorithms for real-time ECG monitoring. First batch rushed to hospitals under emergency authorization, supporting critical care.

The Sharper the Problem, The Solidier the Tech

FATEK's R&D archives hold thousands of "client-specific demands". These requests wear no tech jargon, but hold the real pain points of industries. When challenges strike next time, just bring them to us — you spot the needs, we engineer them into rock-solid solutions.

From factory floors to high-speed trains and hospital emergency rooms, seemingly minor issues can halt entire production lines or even jeopardize lives. While these challenges may lack glamour, FATEK holds firm that such real-world pain points are the very catalysts igniting technological innovation.

The "Angle Blind Spot" in Stamping Presses

Workers struggled to see pressing angles on stamping dies, relying on error-prone guesswork that risked die damage and workplace accidents. FATEK engineers pinpointed the core problem as visual accessibility, not mechanical precision.

Solution: Developed a rotary indicator system with automotive-inspired dynamic light rings for intuitive angle visualization, eliminating guesswork while enhancing operational safety.

The "Vanishing Signal" on Bullet Trains

Controllers malfunctioned due to cabin electromagnetic interference. Clients said: "Works in labs, fails on trains."

Breakthrough: Onboard testing revealed extreme interference. Redesigned circuit boards with shielded chips and anti-interference sealed connectors. Controllers now run stably at high speeds.

The "Lifesaving Button" During COVID-19

When ventilators faced part shortages, FATEK transformed industrial HMIs into medical monitors.

Emergency Fix: Rewrote code and optimized algorithms for real-time ECG monitoring. First batch rushed to hospitals under emergency authorization, supporting critical care.

The Sharper the Problem, The Solidier the Tech

FATEK's R&D archives hold thousands of "client-specific demands". These requests wear no tech jargon, but hold the real pain points of industries. When challenges strike next time, just bring them to us — you spot the needs, we engineer them into rock-solid solutions.