Products

文章隐藏

From Silicon to System: FATEK's Self-Engineered Quality Ecosystem

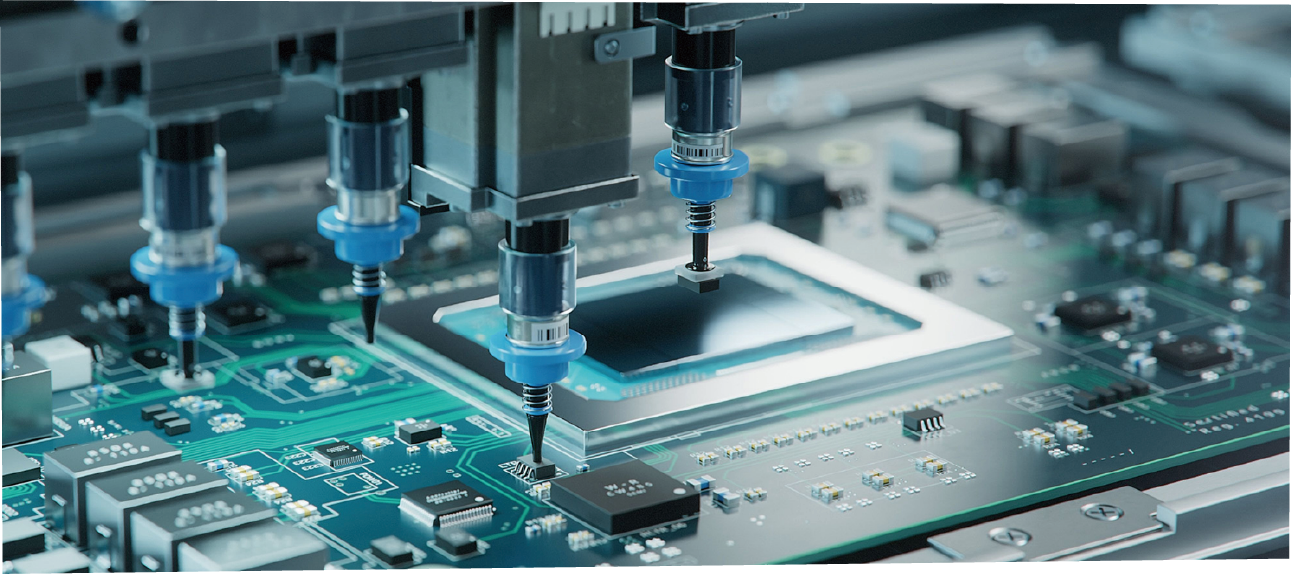

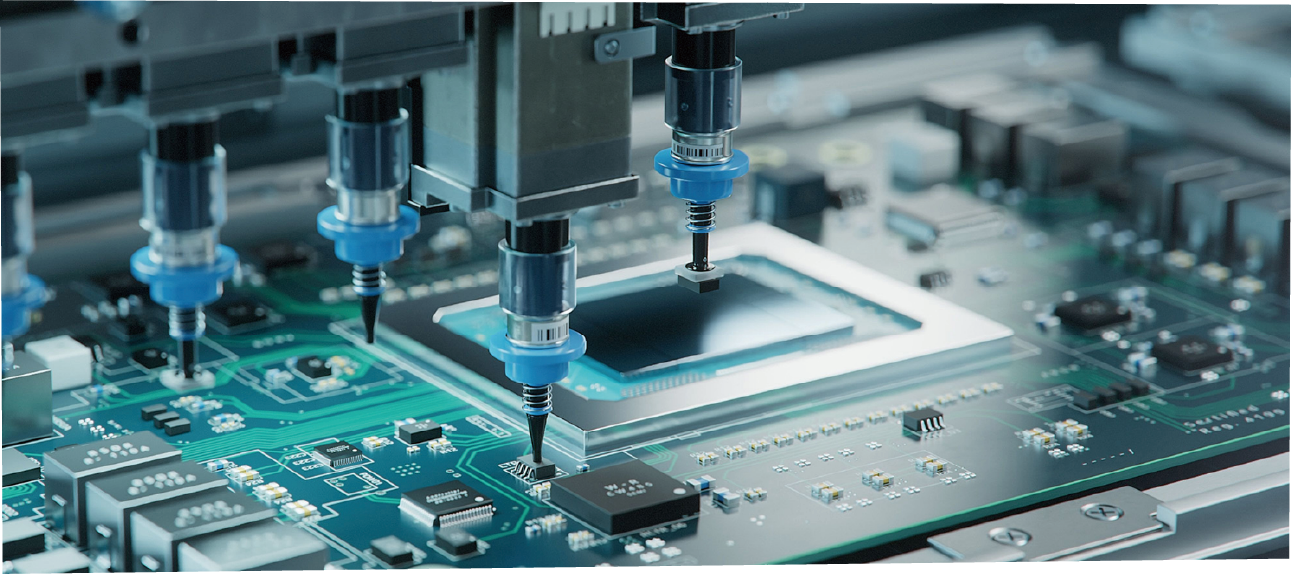

Amid industry-wide pressure on automation equipment lead times, FATEK's fully autonomous SMT production lines enable end-to-end vertical integration from R&D to mass delivery.

not only overcomes the technical responsiveness limitations of traditional ODM models but also establishes rapid iteration cycles, uncompromised reliability, and hyper-customization capabilities as core differentiators – delivering a fortified value proposition for clients.

FATEK's fully autonomous electronics production line integrates core processes including solder paste inspection (SPI), precision component placement, and gas-shielded soldering, establishing end-to-end industrial control board manufacturing capabilities. Equipped with high-precision vision alignment systems and environmental controls, the line ensures micron-level assembly accuracy for miniaturized components, meeting stringent requirements for high-density circuit layouts in industrial equipment.

・Lead-free soldering materials and inert gas-shielded processes mitigate oxidation risks

・Adherence to stringent electronic assembly industry standards guarantees solder joint strength and long-term stability

Before shipment, products undergo multi-stage aging tests and extended operational simulations to proactively identify potential failures through systematic detection protocols. This ensures compliance with rail transit control-grade reliability requirements for long-duration operations, delivering thoroughly validated hardware solutions for industrial automation.

FATEK embeds SOP (Standard Operating Procedures) throughout SMT production lines, enforcing tolerance controls on critical parameters including stencil cleaning frequency, nozzle calibration cycles, and placement pressure thresholds. AOI (Automated Optical Inspection) stations achieve micron-level defect detection (solder voids, bridging, misalignment).

Integrated MES/ERP systems enable end-to-end traceability via unique item coding. This "one-item-one-code" methodology allows forward tracking and reverse tracing for root cause analysis, significantly enhancing post-sales issue resolution efficiency.

In the interplay of precision and efficiency, FATEK holds an unwavering belief – reliability speaks the most heartfelt language in manufacturing.

With micron-level dedication, we nurture the heartbeat of every production line, while data-driven rigor cultivates the soil of innovation. Here, there are no cold machines – only intelligent partners evolving alongside your ambitions. Every solder joint we craft silently powers your next industry-defining breakthrough.

Amid industry-wide pressure on automation equipment lead times, FATEK's fully autonomous SMT production lines enable end-to-end vertical integration from R&D to mass delivery.

not only overcomes the technical responsiveness limitations of traditional ODM models but also establishes rapid iteration cycles, uncompromised reliability, and hyper-customization capabilities as core differentiators – delivering a fortified value proposition for clients.

FATEK's fully autonomous electronics production line integrates core processes including solder paste inspection (SPI), precision component placement, and gas-shielded soldering, establishing end-to-end industrial control board manufacturing capabilities. Equipped with high-precision vision alignment systems and environmental controls, the line ensures micron-level assembly accuracy for miniaturized components, meeting stringent requirements for high-density circuit layouts in industrial equipment.

・Lead-free soldering materials and inert gas-shielded processes mitigate oxidation risks

・Adherence to stringent electronic assembly industry standards guarantees solder joint strength and long-term stability

Before shipment, products undergo multi-stage aging tests and extended operational simulations to proactively identify potential failures through systematic detection protocols. This ensures compliance with rail transit control-grade reliability requirements for long-duration operations, delivering thoroughly validated hardware solutions for industrial automation.

FATEK embeds SOP (Standard Operating Procedures) throughout SMT production lines, enforcing tolerance controls on critical parameters including stencil cleaning frequency, nozzle calibration cycles, and placement pressure thresholds. AOI (Automated Optical Inspection) stations achieve micron-level defect detection (solder voids, bridging, misalignment).

Integrated MES/ERP systems enable end-to-end traceability via unique item coding. This "one-item-one-code" methodology allows forward tracking and reverse tracing for root cause analysis, significantly enhancing post-sales issue resolution efficiency.

In the interplay of precision and efficiency, FATEK holds an unwavering belief – reliability speaks the most heartfelt language in manufacturing.

With micron-level dedication, we nurture the heartbeat of every production line, while data-driven rigor cultivates the soil of innovation. Here, there are no cold machines – only intelligent partners evolving alongside your ambitions. Every solder joint we craft silently powers your next industry-defining breakthrough.