December 16.2025

Automatic Paper Turning and Collecting Machine Solution

| 01 | |

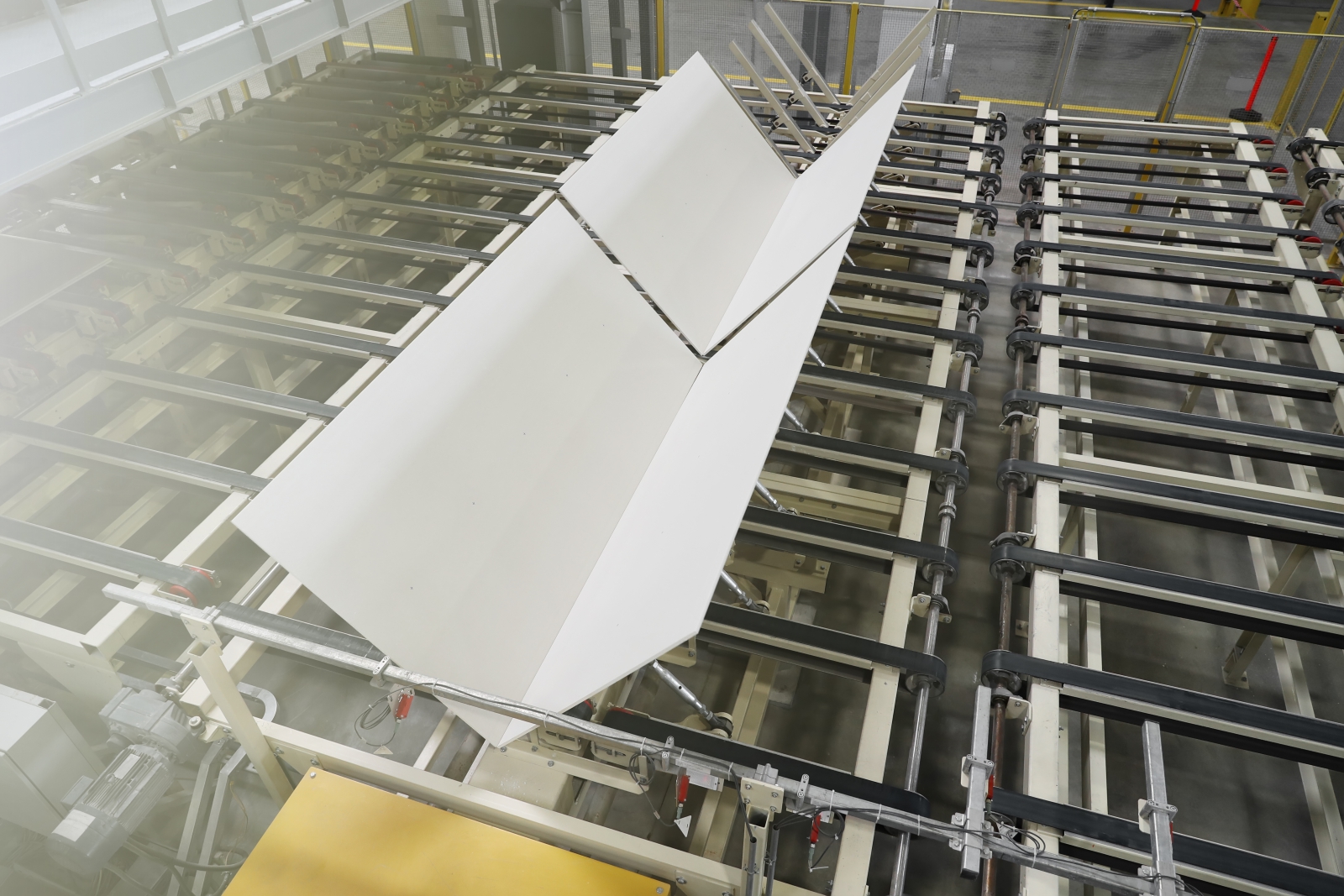

| Project Background The development of the Automatic Paper Turning and Collecting Machine project stems from the printing and post-press packaging industry's increasingly stringent requirements for production efficiency, labor intensity, and finished product quality. In traditional printing production lines, the paper collection stage is often a critical bottleneck for large-format, high-quality double-sided printed materials (such as posters, decorative prints, commercial prints, etc.) or papers requiring specific stacking methods. Traditional paper collection methods, typically involving manual operation or simple mechanical collection, are not only slow and inefficient but also face several core challenges. First, stacking printed materials that are not fully dried can easily cause ink smudging, leading to high scrap rates. Second, manually turning or handling large-format paper is labor-intensive and risks scratching the surface, compromising the quality of the finished product. Furthermore, it is difficult to synchronize the production pace with high-speed printing presses, limiting the overall production line's capacity utilization. | |

| |

| 02 | |

| Efficient and Reliable Professional Solution | |

| This solution aims to build an efficient, stable, and user-friendly control system for an automatic paper turning and collecting machine. The system's core control unit utilizes the FATEK FBs-MA series PLC, which natively integrates four-axis independent high-speed pulse outputs, enabling direct driving of multiple servo motors without the need for additional motion control modules. This highly integrated design not only simplifies the electrical cabinet layout and reduces system complexity and hardware costs but also ensures high-speed and stable transmission of motion control commands, laying a solid foundation for the efficient and reliable operation of the equipment. | |

|

| 03 | |

| FATEK Makes You Stand Out ► Outstanding Motion Control Capability | |

| 04 | |

| FATEK Products Selected in the Solution |