November 10.2025

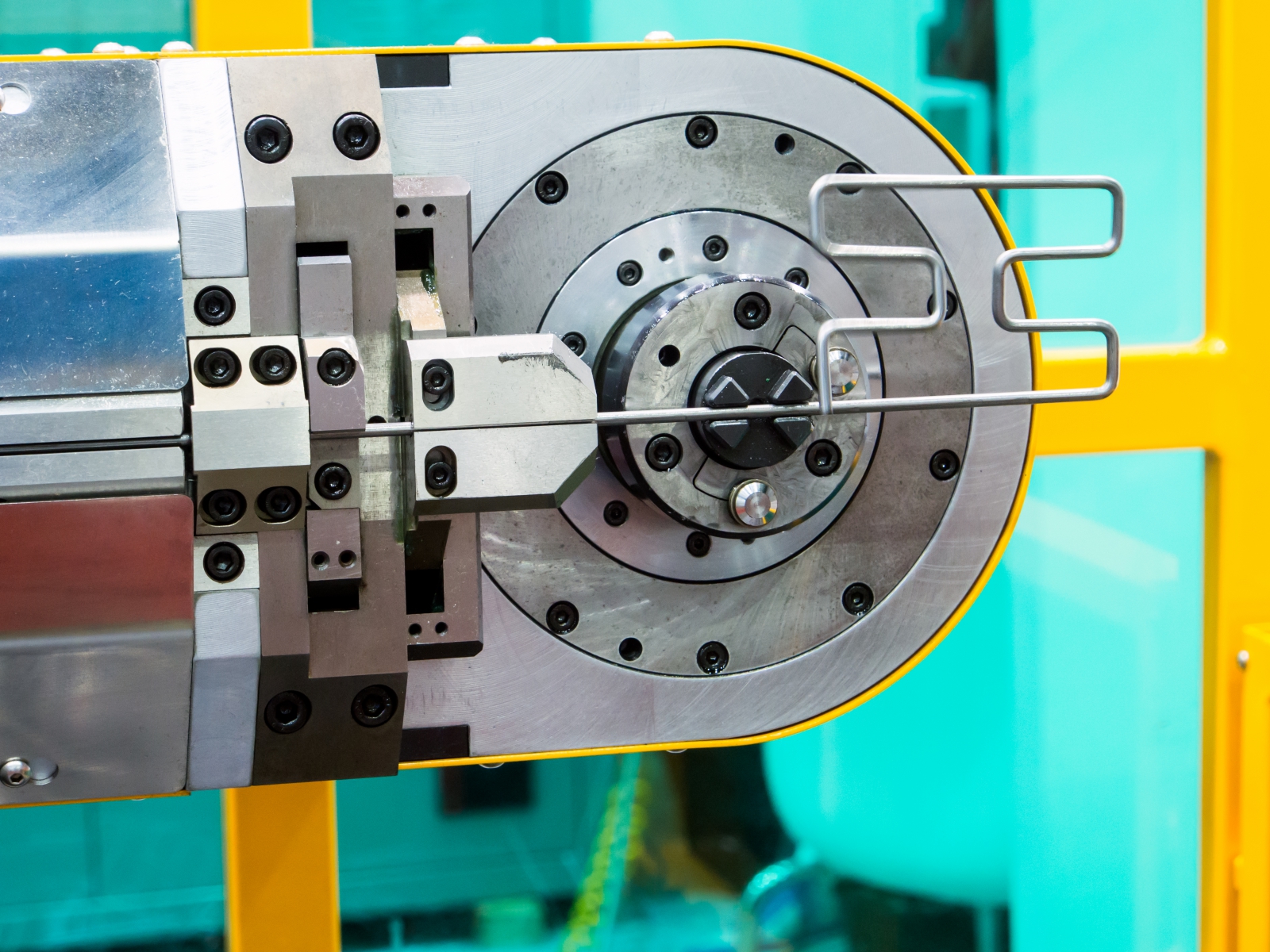

Roller Brush Bracket Bending Machine Solution

| 01 | |

| Project Background Roller brushes serve as fundamental tools in the fields of building construction and industrial painting, with a consistently high market demand. The metal bracket of a roller brush is its core load-bearing component, requiring multiple precise bending processes to ensure sufficient structural strength, reliable clamping force, and accurate connection with the handle during long-term use. | |

| |

| 02 | |

| Efficient and Reliable Professional Solution | |

| According to customer requirements and process control specifications, and after comparing with alternative solutions, the roller brush bracket bending machine's control system utilizes a FATEK FBS series main unit for motion control. This unit controls 4 servo axes to achieve the technical requirements of 4-axis servo positioning control and encoder high-speed counting feedback. The host computer employs a FATEK P5B series HMI as the operation interface, providing functions including automatic operation monitoring, manual operation and debugging, bending parameter setting, I/O monitoring, and alarm message display, while also supporting remote IoT maintenance. The system uses FATEK SC3 series pulse servo motors that work in coordination with the PLC to meet positioning control specifications. A frequency converter is adopted for the feeding turntable to ensure smooth and stable material supply from the front-end material disc. | |

|

| 03 | |

| FATEK Makes You Stand Out

► Superior System Stability and Noise Immunity ► Flexible Production Capability for Various Forming Shapes ► Intelligent Recipe Management Function ► IoT Remote Maintenance Support | |

| 04 | |

| FATEK Products Selected in the Solution |