November 10.2025

CPU Heatsink Rolling & Facing Integrated Machine Solution

| 01 | |

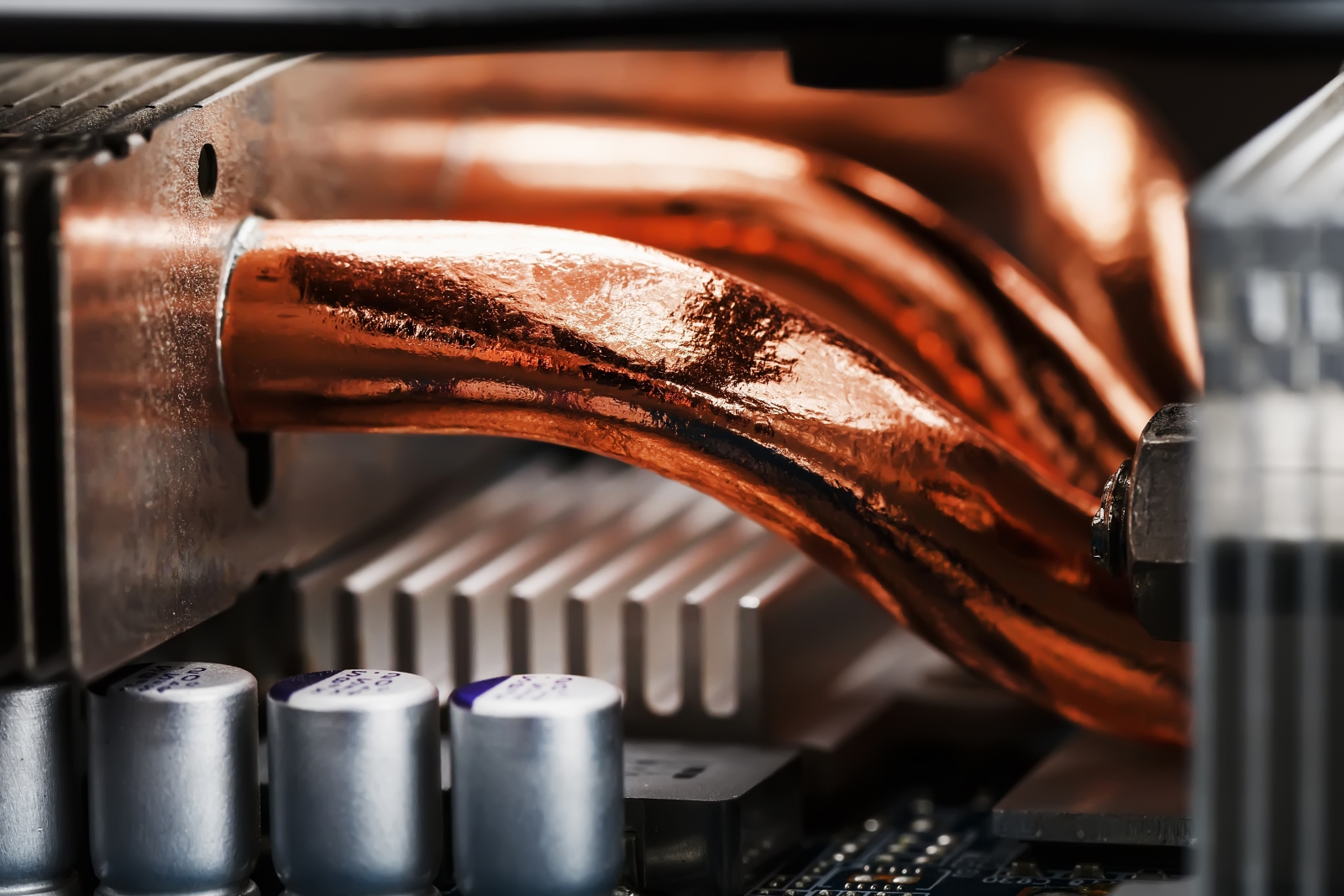

| Project Background In an era of explosive growth in computational demand, the power density of CPUs continues to increase, placing unprecedented demands on thermal performance. As a mainstream cooling solution, the quality of the bond between the base and the heat pipes in a CPU air cooler directly determines the thermal conductivity and ultimate performance of the entire cooling module. In traditional manufacturing processes, "rolling" encapsulation and "facing" finishing are two separate, sequential steps. This discrete production model suffers from numerous drawbacks, including low production efficiency, large equipment footprint, and potential product quality instability caused by repeated positioning errors during transfers between different workstations. | |

.jpg) | |

| 02 | |

| Efficient and Reliable Professional Solution | |

| This solution utilizes a core control system built around the FATEK MQ2M3-1616T main unit (4-axis pulse) plus a 2-axis high-speed output board to precisely control 5 servo motors, achieving fully automatic, integrated operation from heatsink loading, rolling encapsulation, to facing finishing. The FATEK 7-inch touch screen serves as the core of human-machine interaction, integrating equipment status monitoring, production statistics, parameter setting, and fault diagnosis functions. All process parameters, such as rolling pressure, facing depth, and servo speeds, can be modified online and stored via the interface, ensuring operational flexibility and convenience. At the motion control level, the solution makes full use of the 5-axis pulse resources for refined allocation of servo functions. Among these, the spindle movements at the rolling station and facing station demand the highest precision and are prioritized for assignment to the PLC main unit's high-speed pulse outputs, ensuring the stability of the core processes. The remaining auxiliary axes, such as the loading/unloading manipulator and positioning clamps, are driven by the expansion board. Strict interlock logic and state machine processes established within the PLC program ensure accurate, safe, and reliable action sequences for all axes, preventing any interference or collisions. To guarantee long-term stable equipment operation, system reliability design is crucial. A comprehensive fault pre-warning mechanism will be programmed to monitor the status of all servos, limit signals, and abnormal torque in real-time. Any fault can immediately pause the equipment and pinpoint the alarm information. On the hardware level, all pulse signal wires utilize shielded twisted-pair cables with reliable grounding, and power lines are routed separately from signal lines to minimize interference. Through these multiple safeguards combining software and hardware, this solution ensures the integrated machine possesses exceptional stability and durability while maintaining high-efficiency production. | |

|

| 03 | |

| FATEK Makes You Stand Out

► High Integration, Multiplied Efficiency ► Precise Control, Exceptional Quality ► Compact Layout, Optimized Operations | |

| 04 | |

| FATEK Products Selected in the Solution |