November 10.2025

CPU Heat Pipe Feeding Machine Solution

| 01 | |

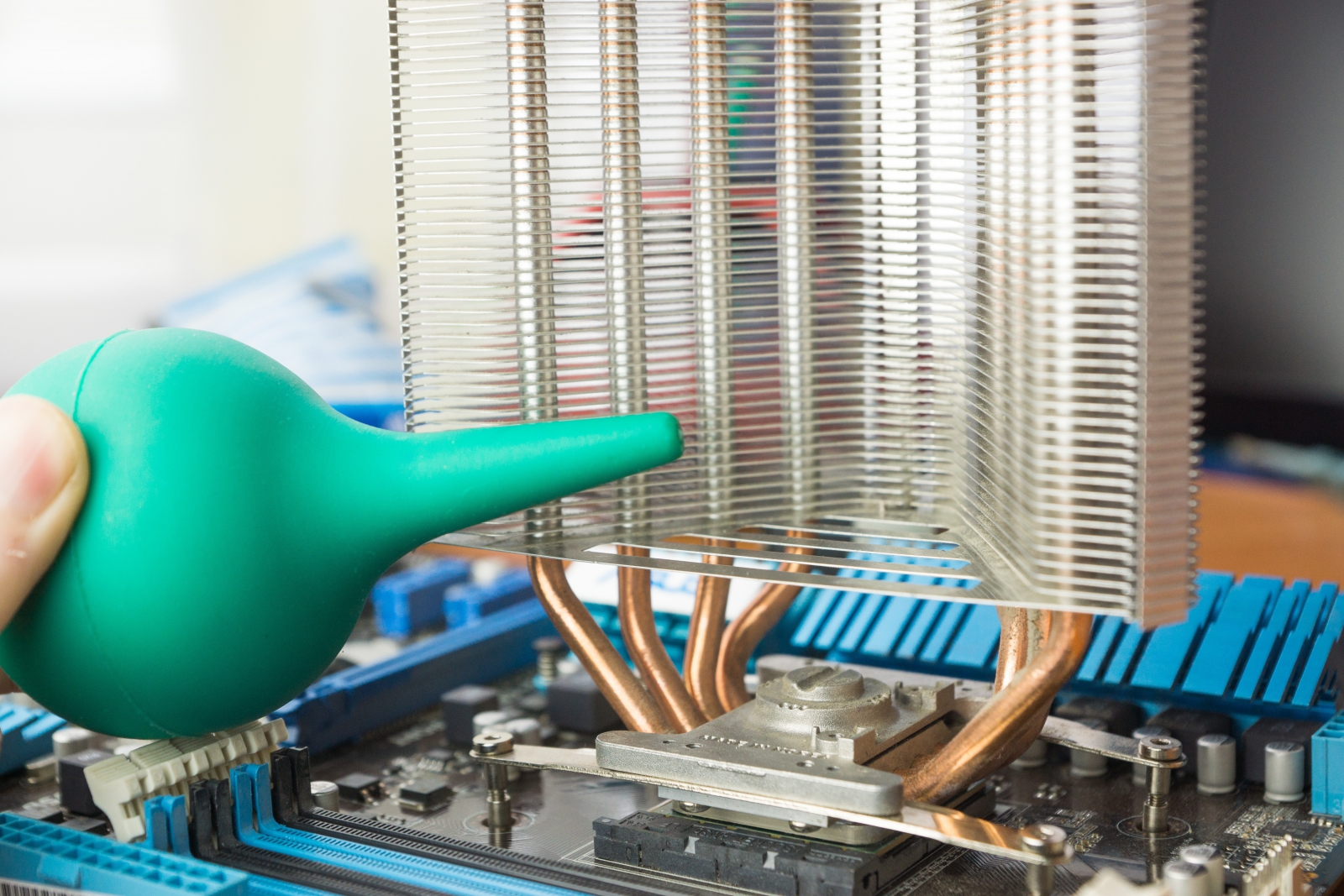

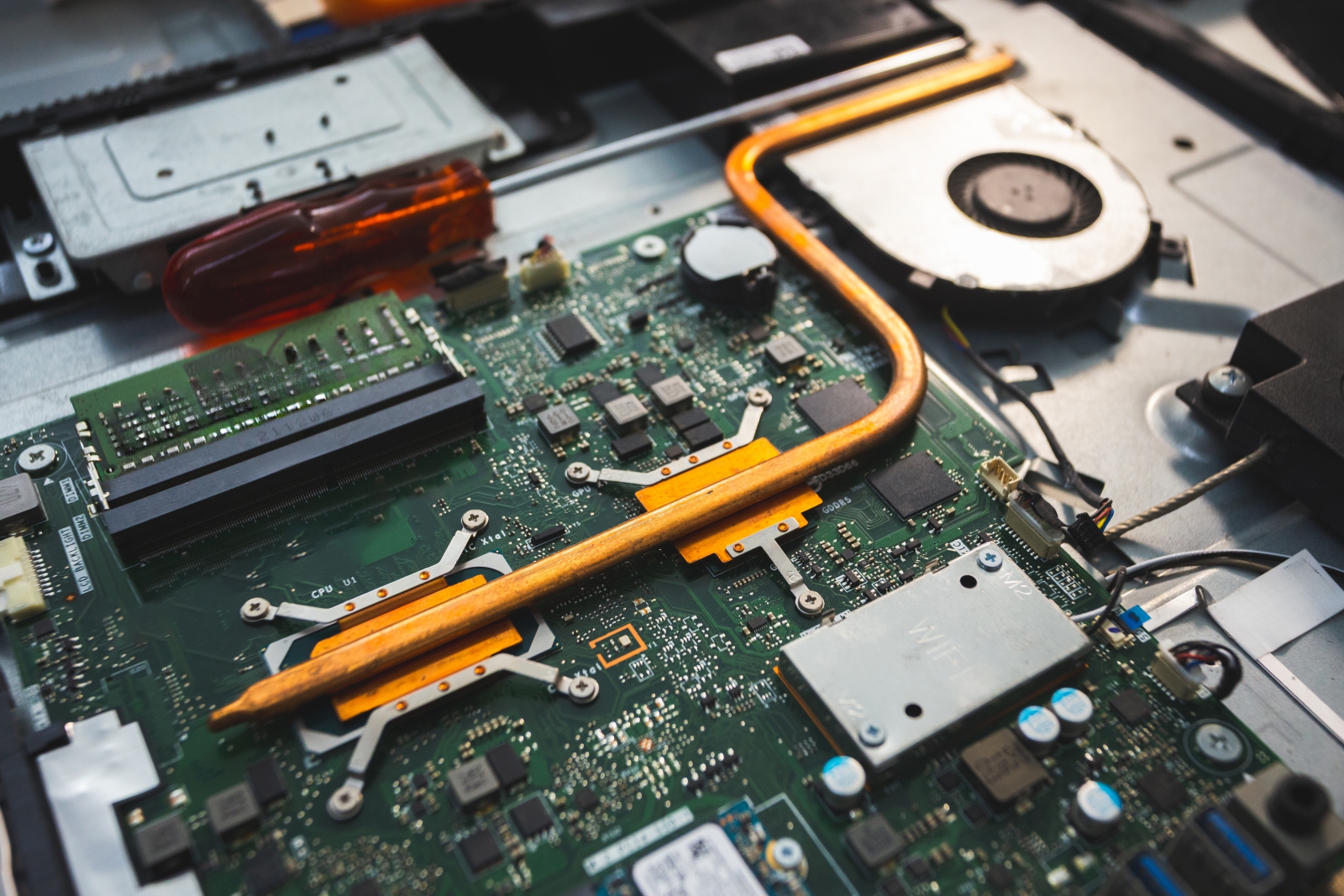

| Project Background With the rapid development of the electronic information industry, the performance of products such as computers, servers, and communication equipment has become increasingly powerful, leading to a sharp rise in the power consumption and heat generation of their core processors (CPUs). Efficient and reliable cooling systems have become crucial for ensuring the stable operation of modern high-performance computing equipment. As the core heat-conducting component within efficient thermal modules, CPU heat pipes are experiencing explosive growth in market demand. In this context, the heat pipe manufacturing process faces severe challenges and upgrade pressures. Traditional manual feeding methods are not only inefficient and slow-paced, struggling to keep up with automated production lines, but also, due to their poor consistency and low positioning accuracy,极易 easily cause bumps, scratches, or even deformation of the precision heat pipes during the clamping process, resulting in high material loss. Furthermore, rising labor and management costs continuously erode corporate profit margins. Therefore, achieving "automation, high precision, and flexibility" in the heat pipe feeding process has become an urgent need across the entire industry chain. The CPU Heat Pipe Feeding Machine project emerges in response to this demand. This project aims to develop specialized automation equipment capable of replacing manual labor to perform automatic grasping, precise positioning, damage-free handling, and accurate installation of heat pipes. It is not only an inevitable choice for increasing production capacity and reducing costs but also a strategic move to ensure product consistency, improve yield rates, and enhance corporate market competitiveness. The successful application of this equipment will mark a critical step for radiator production lines toward full-process automation and intelligence. | |

| |

| 02 | |

| Efficient and Reliable Professional Solution | |

| This solution is dedicated to building a centralized control CPU heat pipe feeding machine based on the FATEK MA1I4-1616T PLC and a 7-inch touch screen. Its core objective is to achieve precise synchronization and efficient collaboration of seven servo motors under the PLC's pulse commands. The touch screen, serving as the equipment's interactive portal, requires deep integration of three major functions: equipment operation, parametric management, and diagnostic maintenance. Operators can initiate/stop the equipment with one touch via its interface and monitor the real-time position, speed, and status of each servo axis. All motion parameters, including taught coordinates for points, speed profiles, and acceleration/deceleration times, support online modification and power-off retention, thereby granting the equipment high process adaptability. In terms of the motion control strategy, we will meticulously plan the responsibilities and motion profiles for the seven servo axes. The servo motor for the picking arm should adopt multi-speed control to balance efficiency and smoothness, while the fine-positioning axis must enable the origin return search mode to ensure repeatable accuracy of the mechanical home position after each power-up. For the servo handling the heat pipe clamping, configuring the torque limit function is recommended to achieve force-controlled gripping and prevent surface imprints on the product. The PLC program will establish a safety interlock chain between the axes through internal status registers; for instance, it ensures the gripper cannot execute a closing action before the transfer arm reaches the picking position, thus forming a solidified safety logic. | |

|

| 03 | |

| FATEK Makes You Stand Out

► Unmatched Efficiency, Soaring Output ► Superior Operations, Lean Production ► Flexible and Adaptable, Multi-Purpose Machine ► Stable and Reliable, Quality Assured | |

| 04 | |

| FATEK Products Selected in the Solution |