July 15.2025

Automatic Punching Machine Solution

| 01 | |

| Project Background The background of the automatic punching machine project stems from the modern manufacturing industry's urgent demand for efficient, precise, and automated processing equipment. With the advancement of Industry 4.0 and smart manufacturing, traditional manual or semi-automatic punching methods can no longer meet the requirements of high-volume, high-precision, and flexible production. Manual operations are not only inefficient but also pose safety risks and struggle to ensure product consistency. Industries such as metal processing, construction materials, home appliances, electronics, and new energy are experiencing growing demand for punching sheets and pipes—products like automotive parts, chassis, steel structures, and solar mounting systems all require high-precision hole processing. Currently, the manufacturing sector faces challenges such as rising labor costs, diversified orders, and shorter delivery cycles, compelling companies to enhance competitiveness through automation. The FATEK SC3 automatic punching machine utilizes CNC systems, servo drives, multi-axis coordination, and other technologies to achieve rapid and precise processing of complex hole patterns. It supports CAD file import and quick mold changes, adapting to small-batch customized production. Meanwhile, IoT technology enables remote monitoring and data analysis, further optimizing production efficiency. Additionally, energy-saving, environmental protection, and workplace safety requirements drive upgrades in automatic punching machines, such as low-noise designs, energy-efficient hydraulic systems, and safety light curtain protection. On the policy front, national manufacturing upgrade strategies (e.g., China's "Made in China 2025") provide strong support for automated equipment. | |

| |

| 02 | |

| Efficient and Reliable Professional Solution | |

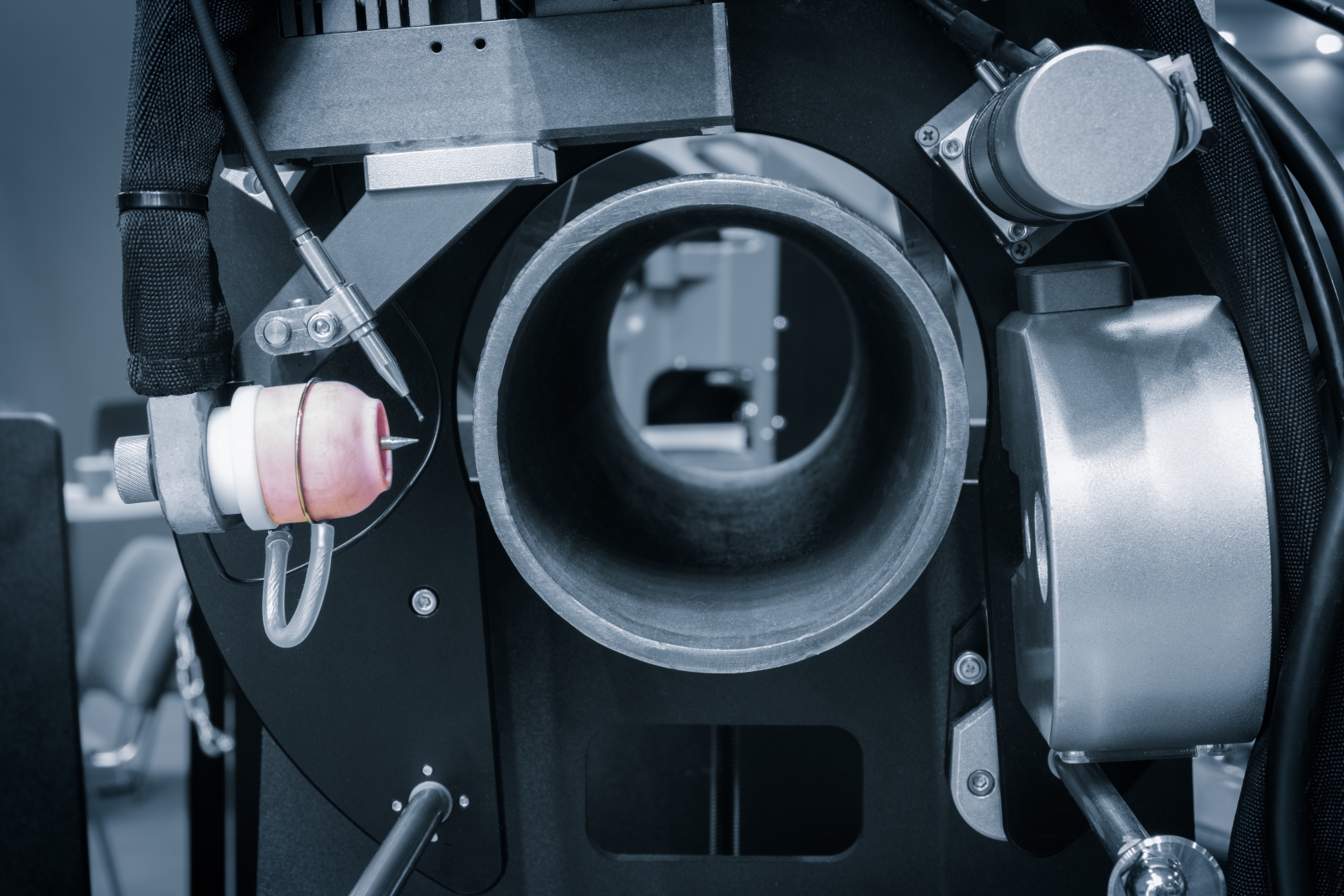

| This solution adopts the FATEK FBs series PLC as the main system controller, paired with the FATEK SC3 series servo motors to form a high-precision motion control system, and integrates the FATEK P5 series HMI for intelligent human-machine interaction. The system fully utilizes the built-in recipe function of the P5 series HMI to enable rapid switching between multiple product processing modes, effectively addressing the inefficiency of traditional punching equipment in model changeovers. With the precise control of the FATEK FBs series PLC and the high-response characteristics of the SC3 series servo motors, the punching process achieves exceptional accuracy and stability. The P5 series HMI offers an intuitive interface and recipe management, allowing operators to easily access preset parameters for quick production switching between different products. This control system significantly enhances production efficiency and product consistency while reducing operational complexity and human error rates, delivering higher productivity and value to customers. The entire system employs FATEK's full product lineup, ensuring excellent compatibility, system stability, and ease of maintenance—making it an ideal solution for modern intelligent punching production. | |

|

| 03 | |

| FATEK Makes You Stand Out ► High-Efficiency Integration, Reliable Performance ► Smart Recipe Management, Flexible Switching ► User-Friendly Operation, Improved Efficiency ► Enhanced Quality, Superior Consistency ► Modular Design, Easy Maintenance | |

| 04 | |

| FATEK Products Selected in the Solution |