July 15.2025

Steel Angle Solution

| 01 | |

| Project Background The background of the dual-servo steel angle production project stems primarily from the increasing demands for precision, strength, and production efficiency in industries such as modern construction, power transmission towers, communication base stations, and rail transportation. Traditional steel angle production methods suffer from issues like insufficient precision, low efficiency, high energy consumption, and material waste, making them inadequate for high-end market needs. With the rapid advancement of smart manufacturing and industrial automation technologies, dual-servo drive technology has been introduced into steel angle production lines due to its advantages in high precision, fast response, and energy efficiency. By precisely controlling the synchronized movement and forming process of the rollers, this technology significantly improves dimensional accuracy, surface quality, and production efficiency. Furthermore, national policies promoting the transformation and upgrading of the manufacturing sector and green production, along with growing market demand for lightweight, high-strength steel, have accelerated the R&D and application of dual-servo steel angle production technology. This project integrates servo control, automated inspection, and intelligent optimization algorithms to achieve high efficiency, precision, and intelligence in steel angle production, addressing the technological gap in high-end steel angle processing equipment in the domestic market and enhancing industry competitiveness. | |

| |

| 02 | |

| Efficient and Reliable Professional Solution | |

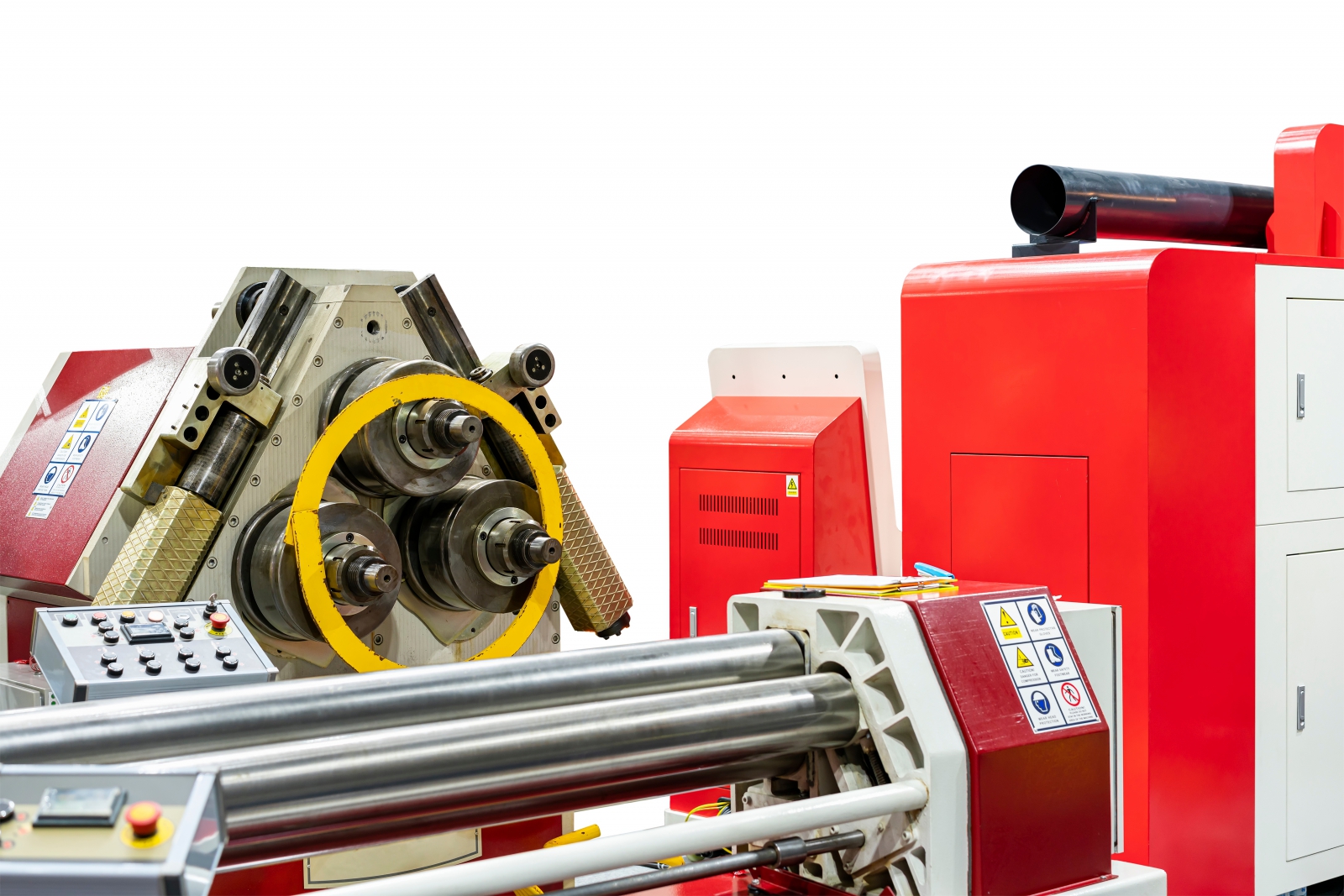

| The dual-servo angle steel production line automation control system adopts FATEK PLC as the core control unit, combined with FATEK HMI, FATEK servo drive system, and supporting detection & execution components to build a highly stable automated production line. The system enhances production accuracy and efficiency through servo synchronous control and intelligent adjustment. The control unit utilizes FATEK FBs series PLC, supporting multi-axis control and industrial communication protocols; the operation unit employs FATEK P5 series HMI for human-machine interaction; the drive unit adopts FATEK SC3 servo system to ensure motion precision; the execution unit consists of pneumatic components and relays; and the detection unit is equipped with various industrial sensors. The system achieves a fully automated production process with features such as high-precision forming, intelligent monitoring & alarms, and energy-efficient operation, significantly improving production efficiency and product consistency. This solution is suitable for high-precision angle steel processing in fields like construction steel structures and power equipment, providing customers with reliable solutions based on FATEK's mature industrial control products, while supporting future intelligent upgrades and expansions. | |

|

| 03 | |

| FATEK Makes You Stand Out ► Precision Control Advantage ► Cost-Effectiveness Advantage ► Stable Production Advantage ► Operational Convenience Advantage | |

| 04 | |

| FATEK Products Selected in the Solution |