June 24.2025

Wastewater Treatment System

| 01 | |

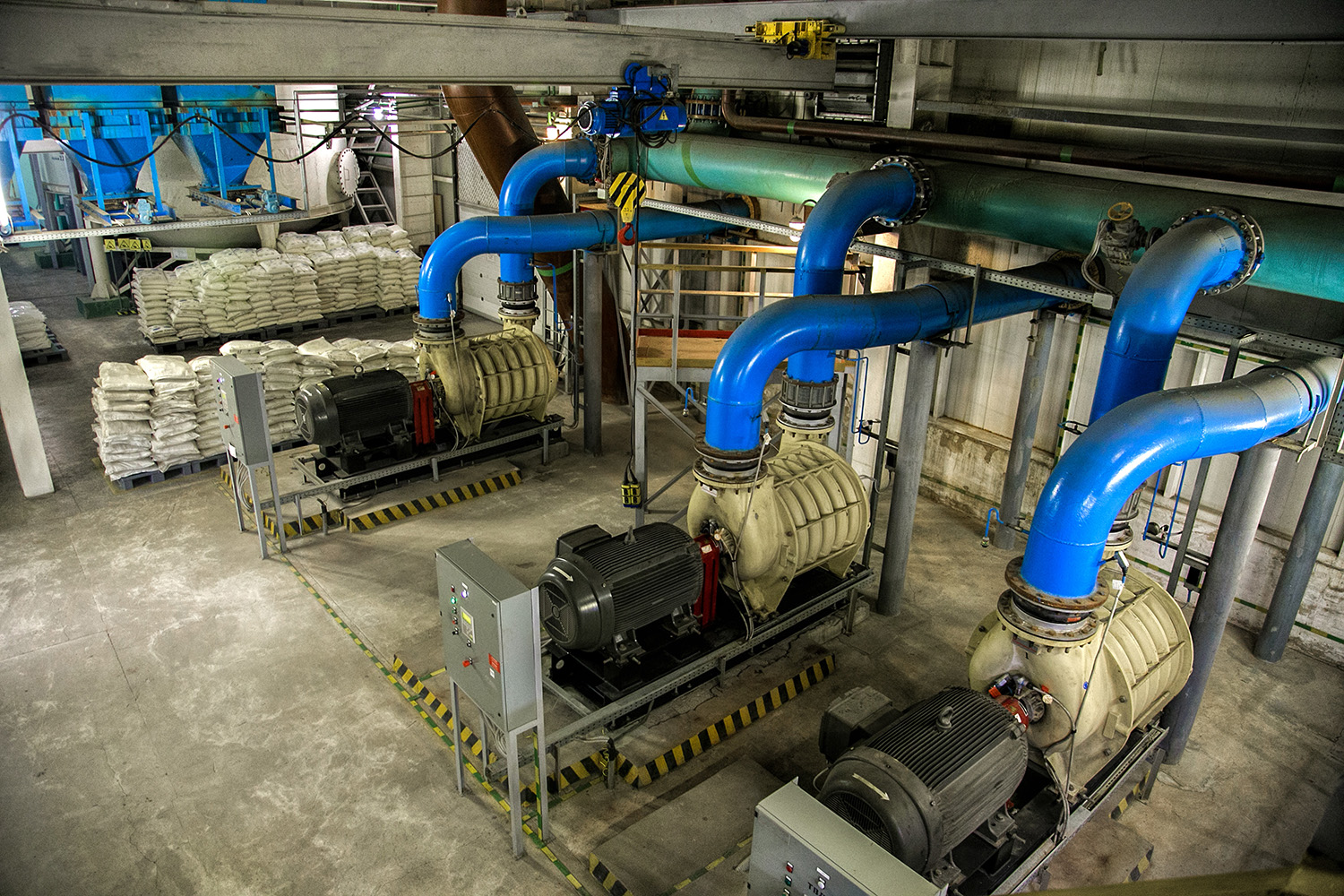

| Project Background With increasingly stringent environmental standards, modern wastewater treatment plants require precise control over the entire process, including pretreatment, biochemical reactions, sedimentation, and disinfection. In harsh operating conditions with high humidity and corrosive gases, the control system must not only coordinate multiple devices such as flow sensors and dissolved oxygen monitors in real time but also withstand the dual challenges of chemical corrosion and electromagnetic interference. Traditional decentralized I/O systems face severe reliability tests. This demands millisecond-level precision control across the entire process—any parameter deviation may lead to non-compliant effluent quality, resulting in heavy fines or even shutdown risks. Challenges include accelerated aging of electrical components due to high humidity and partial corrosion, leading to frequent equipment failures and high annual replacement rates for traditional modules; electromagnetic noise from high-power pump start/stop operations causing frequent signal distortion in pH/dissolved oxygen readings; and inefficient coordination leading to delayed responses in dosing pumps and agitators, affecting water quality compliance rates. | |

| |

| 02 | |

| Efficient and Reliable Professional Solution | |

| To meet the complex and harsh operating conditions and high-precision control requirements of wastewater treatment plants, the system adopts Siemens S7-1200 PLC as the core controller. This PLC features ultra-fast instruction execution speed and a wide operating temperature range, ensuring stable performance in high-humidity and strong electromagnetic interference environments. Its integrated communication interfaces enable high-speed data transmission, laying a solid foundation for precise control throughout the entire wastewater treatment process. Additionally, the distributed acquisition network is constructed using FATEK MC0EN remote I/O modules. With excellent protective performance, these modules can be directly installed in high-risk areas such as aeration tanks and sedimentation basins, effectively overcoming the wiring challenges and signal attenuation issues associated with traditional centralized control systems. In the multi-layer collaborative architecture, the MC0EN remote I/O modules serve as a critical bridge. They efficiently integrate various monitoring devices, including flow meters, dissolved oxygen analyzers, and pH sensors, enabling rapid and accurate data acquisition during wastewater treatment. Simultaneously, as a key hub for execution control, they output control signals to equipment such as agitator variable frequency cabinets, dosing pump units, and sludge return valves. The control system employs advanced algorithms to adjust the agitator speed based on dissolved oxygen concentration in real time. The dosing pump units utilize closed-loop control to precisely regulate chemical dosing according to flow feedback. The sludge return valves dynamically adjust the return ratio based on sludge concentration in the sedimentation tank, ensuring that the activated sludge concentration in the biochemical reactor remains within the optimal range. This guarantees efficient and stable operation across all wastewater treatment processes. | |

|

| 03 | |

| FATEK Makes You Stand Out ► Reliable Operation in Harsh Environments ► Multi-Device Efficiency Breakthrough ► Maintenance & Monitoring Capabilities ► Future-Proof Upgrade Flexibility | |

| 04 | |

| FATEK Products Selected in the Solution |