June 11.2025

Inductor Coil Dispensing Machine Solution

| 01 | |

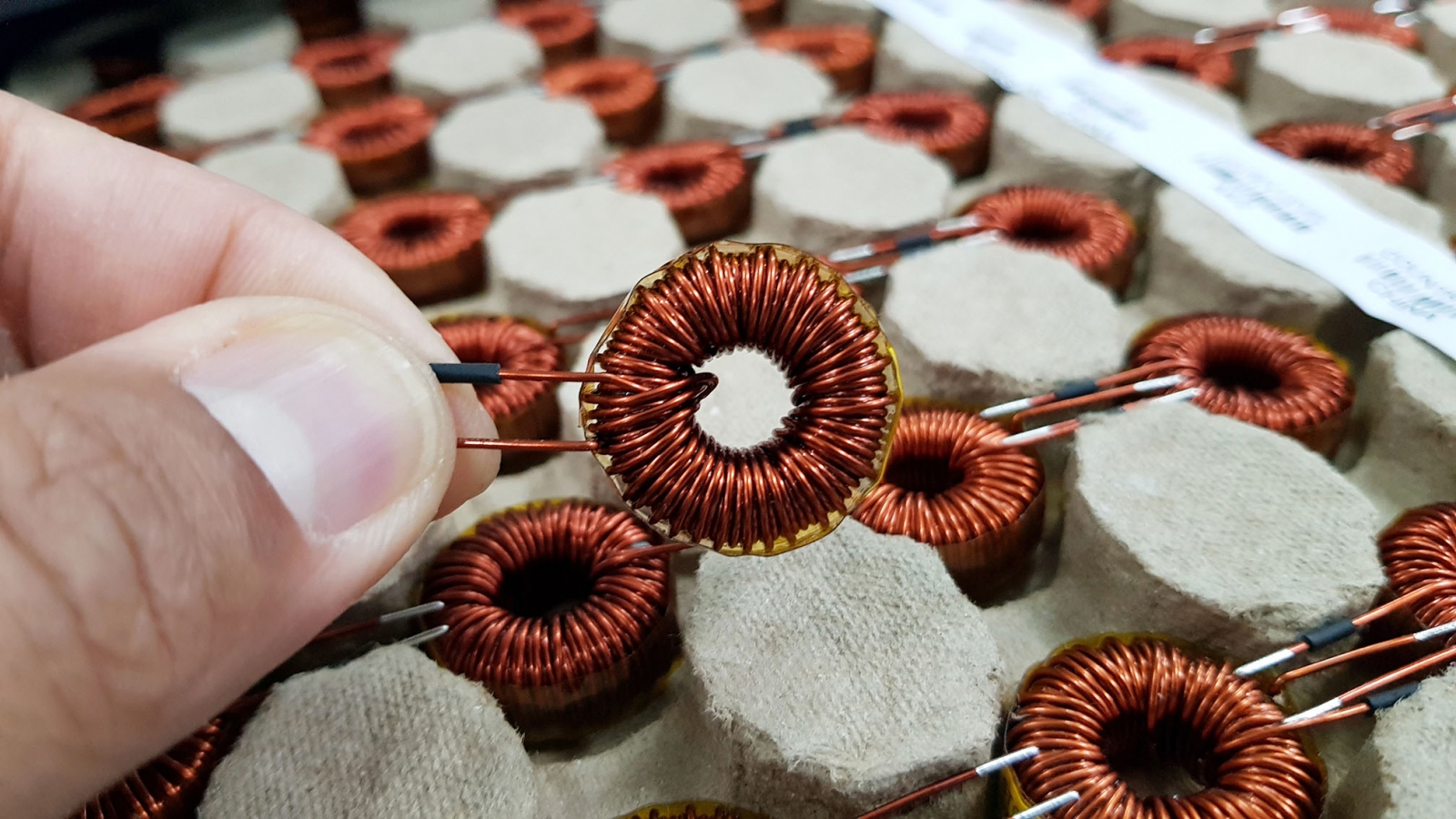

| Project Background With the trend of electronic devices becoming smaller and higher-performing, the demand for inductor coils as key electronic components has significantly increased. They are widely used in power management, communication base stations, new energy vehicles, consumer electronics and other fields. In the manufacturing process of inductor coils, the dispensing process directly affects product reliability and performance, mainly used for coil fixing, insulation protection, moisture-proof sealing and thermal management. Traditional manual dispensing methods are inefficient and struggle to ensure consistency, while general-purpose dispensing equipment cannot meet the high-precision dispensing requirements for the complex structures of inductor coils. Currently, the inductor coil manufacturing industry faces numerous challenges: manual dispensing relies on skilled workers, resulting in low production efficiency and high costs; ordinary dispensing machines have difficulty adapting to different specifications of inductor coils, especially the dispensing requirements for miniaturized and irregular structures; the variety of adhesives (such as UV glue, epoxy resin, silicone, etc.) makes process parameter adjustment complex; moreover, with the development of smart manufacturing, market demands for automation and intelligence in dispensing equipment are increasing, requiring capabilities like high-precision positioning, intelligent glue control, and data traceability. To address these challenges, developing a dedicated automatic dispensing machine for inductor coils has become an urgent industry need. The equipment must have high-precision dispensing capabilities (micron-level control), support multiple adhesive types, adapt to different inductor structures, and collaborate with other production line equipment to achieve efficient and stable automated production. Meanwhile, with the advancement of Industry 4.0 and smart manufacturing, intelligent functions of dispensing machines (such as visual positioning, AI glue shape detection, data monitoring, etc.) will become core competitive advantages, helping the electronics manufacturing industry improve quality, reduce costs, and enhance market competitiveness. | |

.jpg) | |

| 02 | |

| Efficient and Reliable Professional Solution | |

| The equipment control system adopts FATEK M-PLC series medium programmable logic controller as the master station, connecting 16 SC3 series servo drives via EtherCAT bus while controlling another 8 SC3 servos and 1 stepper motor through pulse signals, establishing a high-precision motion control network. The system innovatively utilizes motion table control technology to achieve two-axis circular interpolation and multi-axis continuous path interpolation functions, enabling precise execution of complex dispensing paths. The main control unit is equipped with dual RS485 interfaces and Ethernet ports, where the Ethernet channels respectively establish HMI communication with FATEK P5B series 7-inch touch screen and implement camera triggering and result reading with the vision system through Modbus TCP protocol. This architecture design ensures both real-time performance and accuracy of motion control while enabling flexible configuration of process flows, supporting customized dispensing paths and adhesive volume parameters based on product characteristics, providing a reliable automation solution for high-quality dispensing operations. | |

|

| 03 | |

| FATEK Makes You Stand Out ►Quality Assurance Advantage ►Technical Performance Edge ►Maintenance Efficiency ►Production Flexibility | |

| 04 | |

| FATEK Products Selected in the Solution |