January 08.2025

Three-Axis Pillow Packaging Machine Solution

| 01 | |

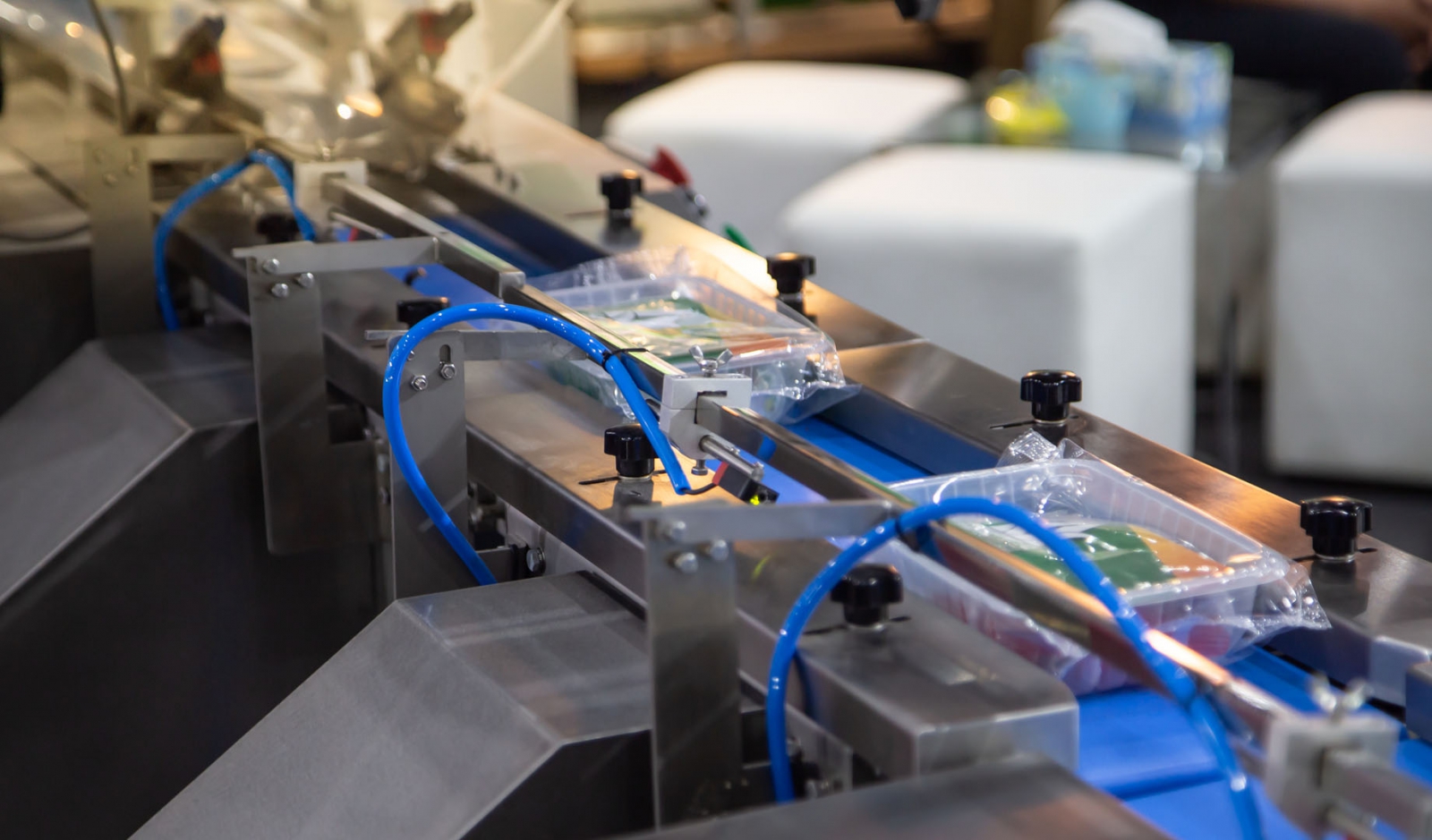

| Project Background The three-axis pillow packaging machine is an advanced packaging equipment with significant roles in the packaging industry. It mainly consists of a feeding mechanism, bag-making mechanism, filling mechanism, horizontal sealing mechanism, vertical sealing mechanism, cutting mechanism, and finished product discharge mechanism. The working principle involves the feeding mechanism conveying the items to be packaged to the bag-making mechanism, where bags are formed, filled with items, sealed by the horizontal and vertical sealing mechanisms, and finally cut and discharged by the cutting mechanism. | |

| |

| 02 | |

| Efficient and Reliable Professional Solution | |

| In terms of control system configuration, careful selections have been made. The upper-level machine adopts the FATEK P5 series touch screen, which plays a crucial role in providing a convenient operation interface for equipment debugging, allowing operators to easily make precise adjustments to various parameters. In manual operation mode, it also provides clear command feedback, ensuring that every operation step is accurate and error-free. For the core control part, a M series PLC is selected. This PLC, with its stable performance and efficient computing capabilities, provides a solid guarantee for the smooth operation of the three-axis pillow packaging machine. It can precisely control the actions of each mechanism, ensuring the accuracy and consistency of the packaging process. In the servo system aspect, the choice is made for FATEK high-performance SC3 servo. This servo system is characterized by fast response, high precision, and strong stability, meeting the three-axis pillow packaging machine's demands for high-speed and high-precision packaging. Moreover, the PLC and servo are connected and controlled through the EtherCAT bus method. This advanced communication method not only enables high-speed data transmission but also ensures the timeliness and accuracy of control signals, further enhancing the overall performance and production efficiency of the three-axis pillow packaging machine. | |

|

| 03 | |

| FATEK Makes You Stand Out ► High Precision Packaging 1. Advanced three-axis control system: The three-axis pillow packaging machine uses an advanced three-axis control system, which can achieve precise position control and speed control. This allows the packaging machine to accurately position the packaging items during the packaging process, ensuring packaging accuracy and quality 2. High-precision sensors: The packaging machine is equipped with high-precision sensors that can monitor various parameters in the packaging process in real-time, such as the position, speed, and tension of the packaging items. These sensors can feedback the monitored data to the control system, allowing the control system to adjust packaging parameters in time, ensuring packaging accuracy and quality 3. High-quality packaging materials: The three-axis pillow packaging machine can use various high-quality packaging materials, such as plastic films, paper, aluminum foil, etc. These packaging materials have good flexibility, sealing, and wear resistance, ensuring that the packaging items are not damaged during the packaging process, while also improving the aesthetics and grade of the packaging ► Efficient Production 1. High-speed packaging: The three-axis pillow packaging machine has the capability for high-speed packaging, allowing it to complete a large number of packaging tasks in a short time. This gives the packaging machine a significant advantage in large-scale production, increasing production efficiency and reducing production costs 2. High degree of automation: The packaging machine employs advanced automation technology, enabling automatic feeding, automatic bag making, automatic filling, automatic sealing, automatic cutting, and a series of other operations. This allows the packaging machine to operate without manual intervention during the production process, greatly improving production efficiency and reducing labor intensity 3. Multifunctionality: The three-axis pillow packaging machine is multifunctional and can adapt to the packaging needs of packaging items of different shapes, sizes, and materials. This gives the packaging machine higher flexibility and adaptability during the production process, meeting the needs of different customers ► Stable and Reliable 1. High-quality components: The packaging machine uses high-quality components, such as motors, reducers, sensors, controllers, etc. These components have good performance and reliability, ensuring the stable and reliable operation of the packaging machine over the long term 2. Strict quality control: The packaging machine strictly adheres to quality control standards during the production process, conducting rigorous testing and inspection of each component and every step. This ensures that the packaging machine meets high-quality standards before leaving the factory, ensuring stable and reliable operation during use 3. Comprehensive after-sales service: The packaging machine manufacturer provides comprehensive after-sales service, which can promptly solve various problems customers encounter during use. This allows customers to use the packaging machine without worries and with confidence | |

| ► Energy-saving and Environmental Protection 1. Low energy consumption: The three-axis pillow packaging machine uses advanced energy-saving technology, which can reduce energy consumption during the packaging process, saving energy. This results in lower operating costs for the packaging machine during use, while also meeting energy-saving and environmental protection requirements 2. Pollution-free: The packaging machine does not produce any pollutants during the packaging process, such as exhaust gas, wastewater, waste residue, etc. This ensures that the packaging machine does not pollute the environment during use, complying with environmental protection requirements 3. Recyclable and reusable: The packaging materials used by the packaging machine are mostly recyclable and reusable, such as plastic films, paper, aluminum foil, etc. This allows the waste generated by the packaging machine during use to be recycled and reused, reducing resource waste and meeting the requirements for sustainable development  | |

| 04 | |

| FATEK Products Selected in the Solution |