January 08.2025

Motor Stator and Rotor Shaping Machine Solution

| 01 | |

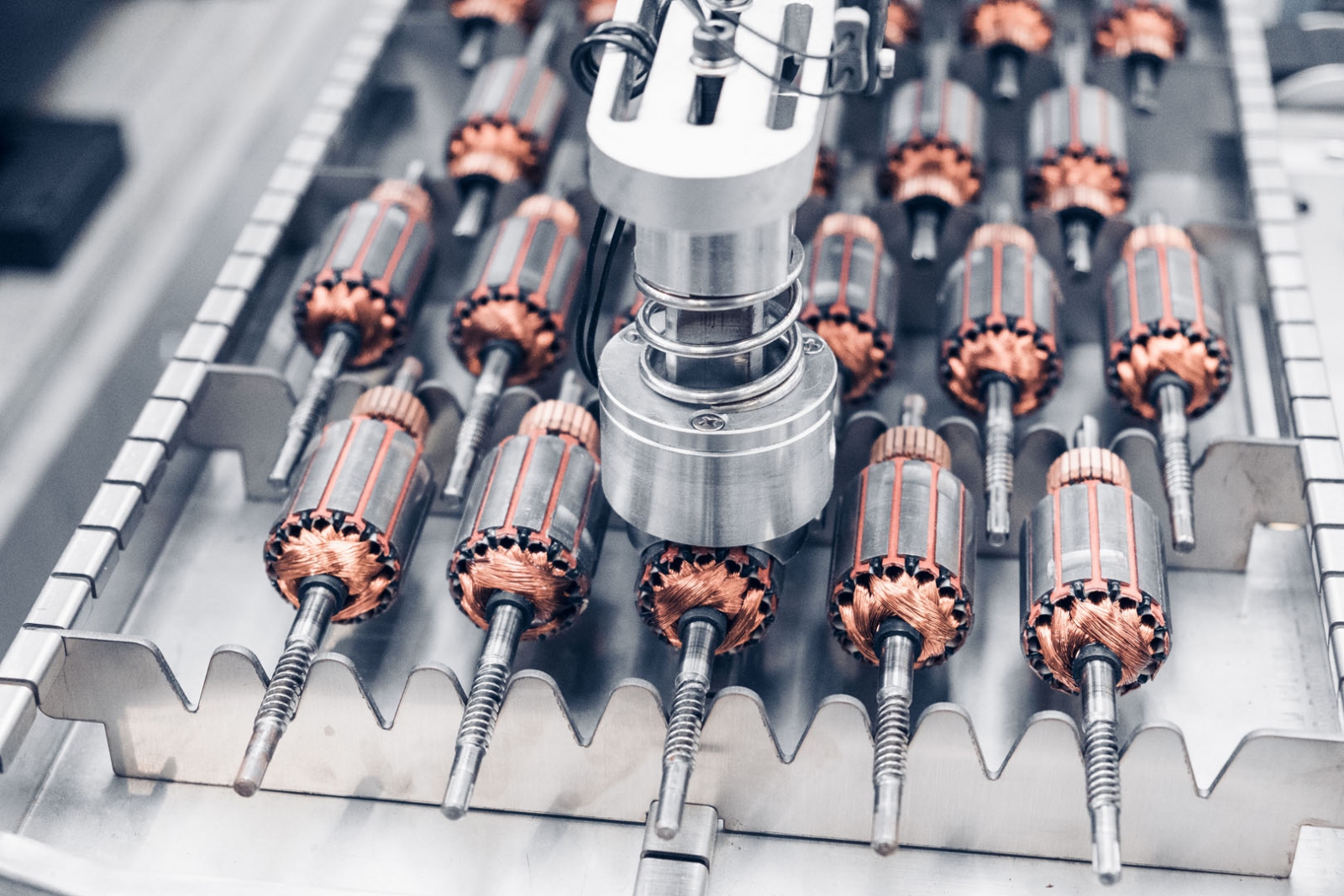

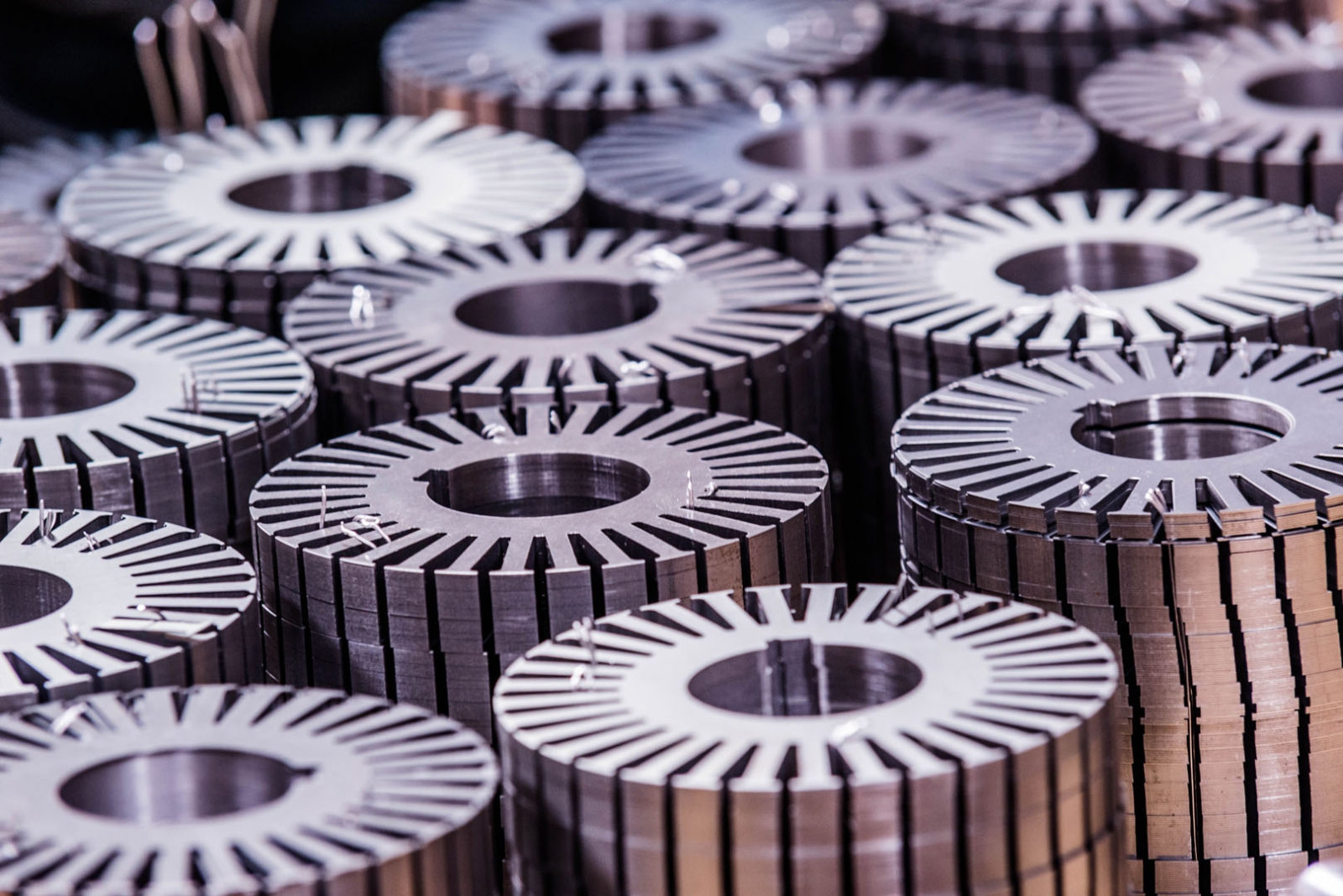

| Project Background The motor stator slotting machine plays a crucial role in the shaping process of stators and rotors in automotive generators. Its workflow is scientific and efficient. Firstly, it can accurately stack the stator and rotor according to the pre-set angles for each layer in an orderly manner. | |

| |

| 02 | |

| Efficient and Reliable Professional Solution | |

| The motor stator slotting machine is equipped with a brand-new FATEK M-series PLC main unit, paired with 8 units of the SC3 series EtherCAT bus-type servo motors and 2 stepper motors. Through advanced motion control methods, it achieves tight coordination of multi-axis motion processes and rapid, precise positioning control. The main unit integrates two 485 ports for machine communication, allowing for the real-time retrieval of camera inspection results and stepper motor angle correction. Additionally, the integrated measurement channels can instantly obtain press force, ensuring the press force is within the required range. The machine's workflow includes steps such as material loading, stator or rotor grasping, visual inspection and positioning, angle correction (with repeated photography and comparison until the angle is OK), visual re-inspection, stacking (with 6 layers of rotors and 7 layers of stators forming a complete product, with angle deviation within 0.05 degrees), press molding, data measurement and recording, and finished product output. The stator and rotor stations work independently without affecting each other, and each layer's material grasping and correction must be completed within 30 seconds. This equipment has many advantages, with high-precision control achieved through advanced motion control methods and visual inspection systems, ensuring product quality. Efficient production is due to a reasonable workflow and fast operation times, meeting the needs of large-scale production. Real-time measurement and recording of finished product data provide strong support for product quality analysis and process improvement, enhancing corporate management standards. The independence of the stator and rotor stations allows for simultaneous production, increasing equipment utilization rates. | |

|

| 03 | |

| FATEK Makes You Stand Out ► Exceptional Performance for High-Demand Production Scenarios In the production process, due to the uncertain angles at which each product is ejected from the press, this poses extremely high requirements for the control system's processing speed. The M-PLC in the solution executes each LD (ladder) instruction in just 0.8 ns, ensuring such high-speed processing capability to guarantee the accuracy of the corrected angles. Even when facing products with unpredictable angles, it can quickly respond to ensure that each product's angle is precisely corrected. At the same time, the EtherCAT bus solution controls multiple axes of servos, meeting the demands for high-speed and high-precision control, providing a solid guarantee for product quality. ► Convenient Maintenance and Efficient Remote Operation The P5 series high-end touch screen supports VNC (Virtual Network Computing) remote operation and monitoring, a feature that brings great convenience to customers. In terms of equipment maintenance, it facilitates remote operation of the equipment and remote uploading and downloading of programs, greatly saving customers' maintenance costs. There's no need for technical personnel to be on site; the equipment can be monitored and maintained remotely, improving maintenance efficiency, reducing equipment downtime, and ensuring the continuity of production. ► Rapid Response and Dual CPU Concurrent Execution The M-PLC main unit features a dual CPU design (PLC CPU + Motion CPU), with the control and motion control operating independently. This design allows the dual high-performance control centers to execute concurrently, with the upgraded M-PLC's LD instruction execution time being 0.8 ns, nearly 500 times faster than the previous generation FBs series. The additional Motion CPU is primarily responsible for the execution of motion control and is not affected by the Ladder program's scan cycle, ensuring high-speed and high-precision control. When facing complex production tasks and high production rhythms, it can respond quickly and accurately execute various commands, improving production efficiency. | |

| ► High-Precision Execution Components and Convenient Adjustment The execution components use the FATEK SC3 series EtherCAT bus-type servo motors. Based on the EtherCAT communication method, the SC3 series products have a fastest synchronization period of 125us, meeting the requirements for high-speed and high-precision control. Coupled with the efficient and convenient ProTuner tuning software, the equipment adjustment is more intuitive. In actual production, it can ensure the equipment's high-precision operation, improving product quality and consistency. At the same time, the convenient adjustment software reduces the difficulty and time cost of equipment tuning, providing strong support for businesses to quickly start production.  | |

| 04 | |

| FATEK Products Selected in the Solution |