June 24.2025

High-Speed Punch Press and NC Feeding Solutions

| 01 | |

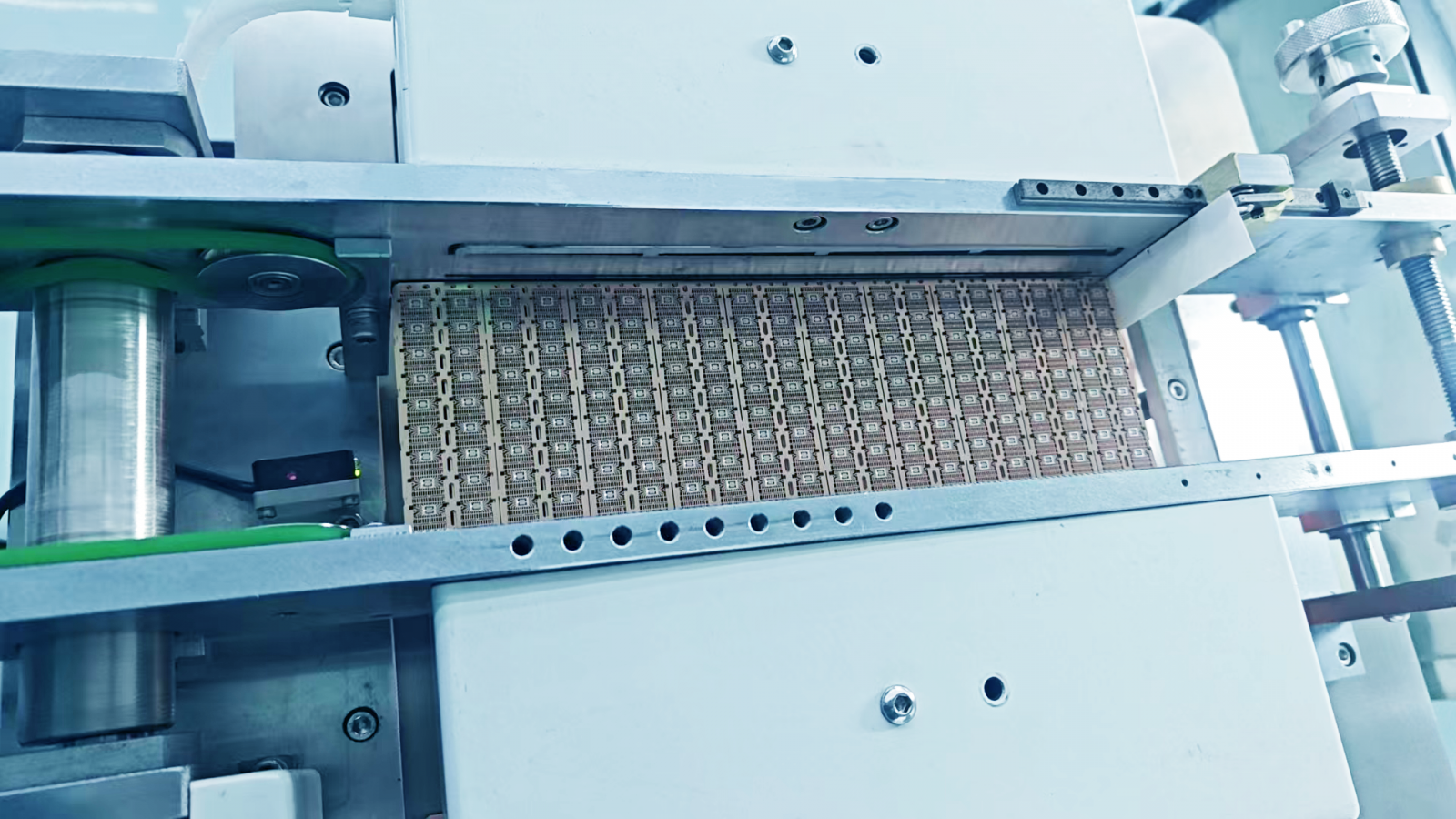

| Project Background Amid the increasingly intense global technology competition and the national strategy to promote the autonomous and controllable integrated circuit industry, the self-production capability of chips has become a key indicator of a country's technological strength. As a critical carrier for chip packaging, the quality, precision, and production efficiency of lead frames directly impact the performance, reliability, and manufacturing cost of chips. Therefore, providing high-performance and high-stability production equipment for the lead frame manufacturing industry holds extremely important strategic significance and market demand. Traditional lead frame production primarily relies on ordinary punch presses or early automated equipment, which suffer from issues such as low production efficiency, insufficient precision stability, and low material utilization rates. These limitations make it difficult to meet the technical requirements of modern chip packaging, which is evolving toward miniaturization, multi-pin, and high density. For example, advanced packaging forms such as QFN and DFN impose micron-level requirements on the flatness, pin coplanarity, and etching or stamping dimensional accuracy of lead frames. At the same time, with the rapid development of industries like 5G, the Internet of Things, artificial intelligence, and automotive electronics, market demand for chips has surged. This necessitates that upstream lead frame production achieve high efficiency, large scale, and low cost. Driven by this series of urgent demands, automated production line solutions combining high-speed punch presses with high-precision NC (numerical control) feeders have become an inevitable choice for modern lead frame production. This project aims to develop and manufacture core equipment specifically for precision lead frame production. High-speed punch presses can perform precision stamping at speeds of hundreds or even thousands of strokes per minute, ensuring extremely high production efficiency. Meanwhile, the accompanying NC feeding system, through precise servo control technology, achieves micron-level accurate positioning of the feeding step, guaranteeing stamping precision at every station and thus producing highly consistent products. | |

| |

| 02 | |

| Efficient and Reliable Professional Solution | |

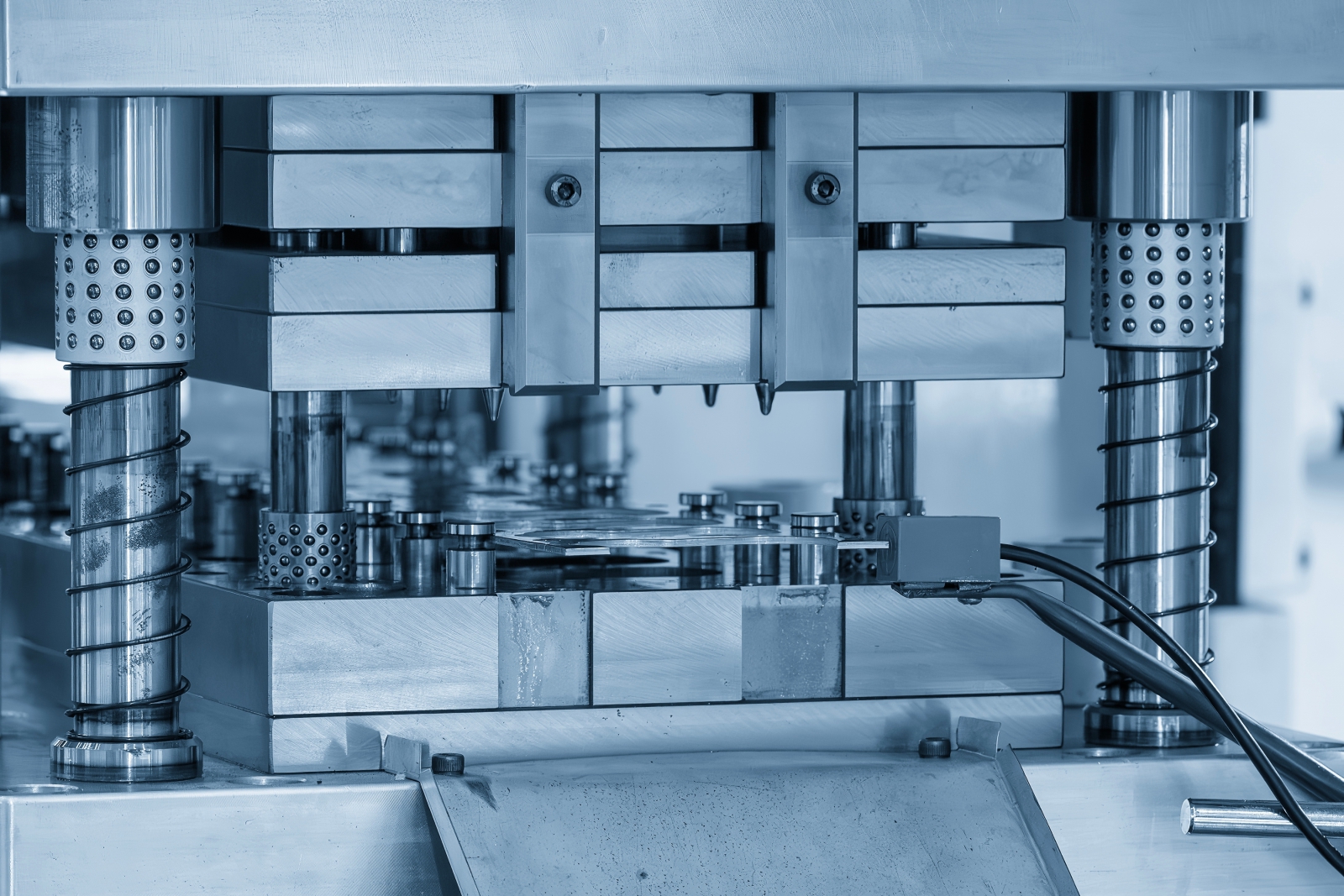

| At the hardware architecture and control system level, this equipment adopts the SC3 controller as its core hub, equipped with the EtherCAT high-speed industrial Ethernet communication protocol, establishing a stable and reliable control network to achieve precise driving of two bus servos. This architectural design not only ensures millisecond-level synchronization of inter-axis motion but also eliminates network transmission delays through distributed clock technology, maintaining stable and smooth operation even under complex and variable working conditions. The human-machine interface system utilizes the P5B touchscreen, featuring an intuitive and user-friendly graphical interface that allows comprehensive and fine-tuned adjustment of equipment operating parameters. Whether setting the feed length, adjusting the operating speed, or calibrating the cutting timing, users can perform "what-you-see-is-what-you-get" real-time modifications via the touchscreen. This significantly enhances operational convenience and process flexibility while drastically reducing production preparation time. The built-in closed-loop frequency converter employs advanced vector control algorithms and real-time feedback to dynamically optimize motor speed and torque. Working in deep collaboration with the servo system, it utilizes micron-level position compensation and dynamic inertia matching technology to greatly improve the positioning accuracy of the feeding system. Even during high-speed operation, it ensures efficient and precise feeding and cutting of electronic sheet materials and IC components, providing solid and reliable technical support for the electronics manufacturing industry. | |

|

| 03 | |

| FATEK Makes You Stand Out ► Advanced Motion Control System ► Intelligent Diagnostics & Maintenance

► High-Reliability Design

| |

| 04 | |

| FATEK Products Selected in the Solution |