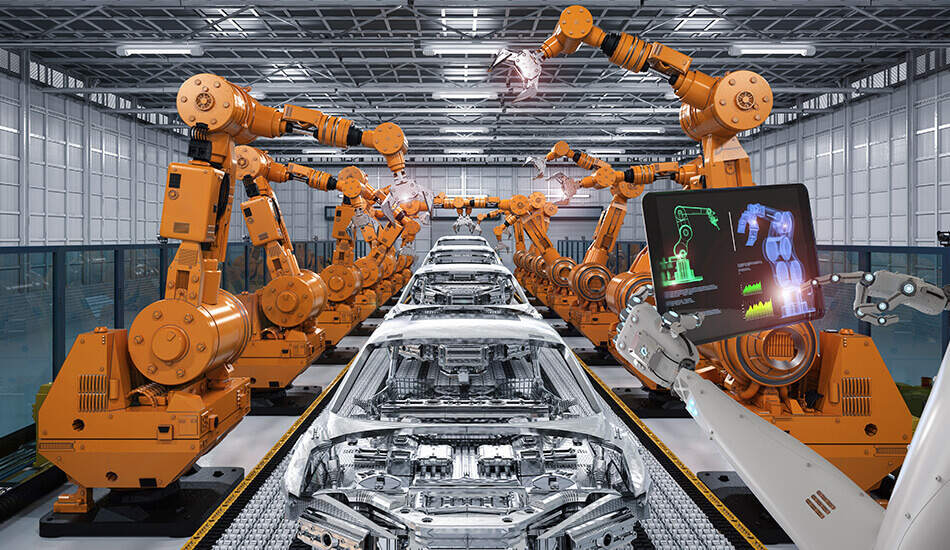

CAR PRODUCTION LINE

The auto industry is a comprehensive industry that is developed based on many peripheral industries and related technologies. Aside from the complicated and accurate control performance requirement to controllers, their environmental resistance and reliability are also extremely required during the production process. During the car body shell stamping process, the reciprocal accuracy is required for ensuring consistent thickness. The production line conveyor must work smoothly having good stability to prevent parts from loosening during assembly. In the paint coating room, the temperature control is stringent. Inaccurate heating may cause a painting defect. In the assembly area, reliable testing jigs and the man-machine interface that is easily operable and stable are needed for assisting people in assembling.- Car production line

- Stamping press

- Assembling

- Conveyor

- Paint baking

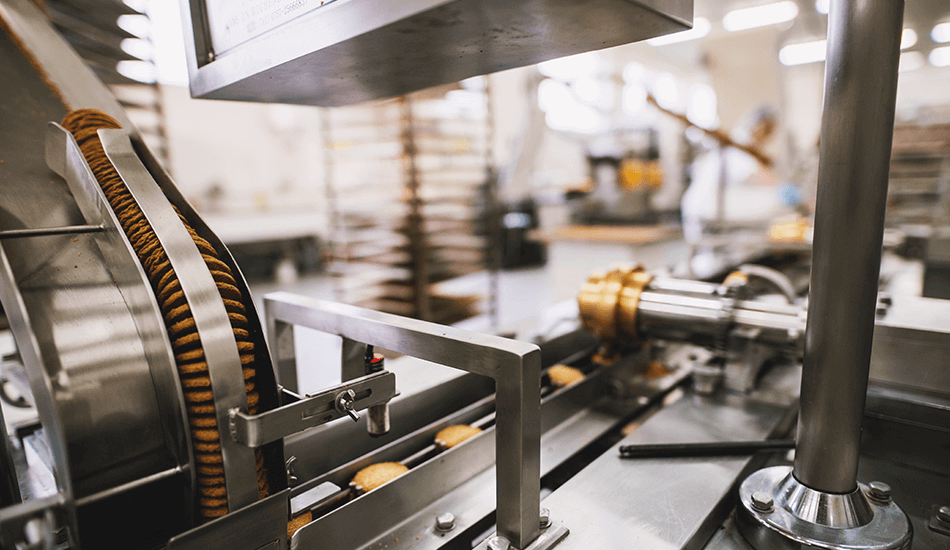

FOOD INDUSTRY

The way of food cooking has been expanded from the chef’s hand in the kitchen to the automatic production equipment in the central kitchen. How to cook for the same taste and flavor with the facility as cooked by the chef can only be achieved by adjusting each production parameter and monitoring all details with a stable controller. A dough rolling machine has to work accurately and synchronously with its multi-shafts to evenly flatten the dough. The container injection device must respond quickly to accurately control the injected capacity. The heating system shall have accurate control of temperature for getting the desired flavor. The packaging machine then shall quickly wrap up the food for ensuring that the freshness of food ingredients is maintained.- Rolling machine

- Container injection

- Heating

- Packaging

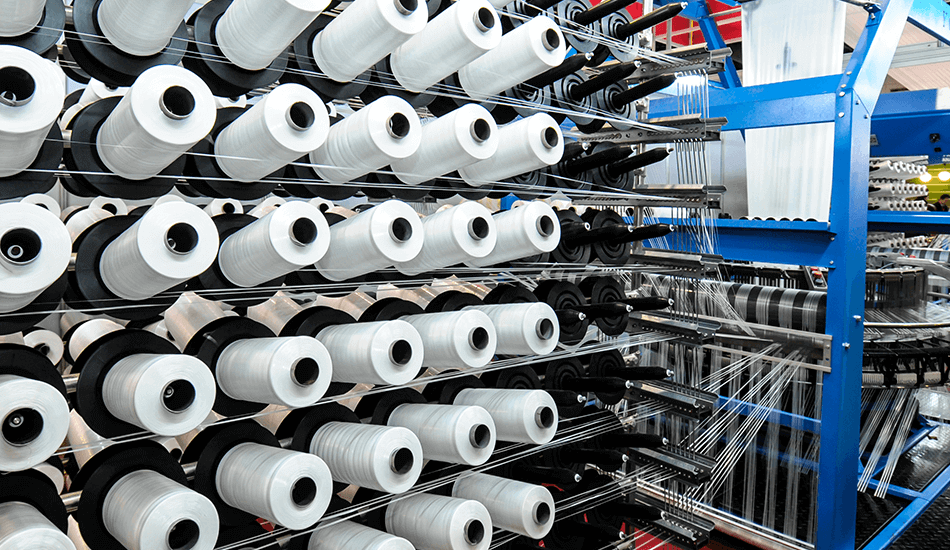

TEXTILE INDUSTRY

Textile manufacturing can be made not only for clothes to wear. Through complicated techniques of weaving and stacking layer by layer, it can also be made into some picturesque multi-layer beautiful crafts. Along with the progress of industrial automation, today, we can also make beautiful apparel by using a textile machine, which could only be made by a skillful tailor in the past. Tangled fibers need to be loosened by rolling, beating, pulling and tearing. However, the controller must continue to work steadily by resisting noises from a complex environment and vibration. The weaving process relies on very quick weaving of threads. It has a high requirement for performance and accuracy to the controller. In dyeing and finishing, heating up chemicals for mixing and toning is required. Color fastness has to be done after dyeing. During this process, accurate temperature is required to ensure that dyestuffs are firmly attached to different materials.- Spinning machine

- Weaving machine

- Dyeing and finishing